The pipe insulation market is poised for substantial growth over the next decade, driven by several key factors that are reshaping the industry landscape. As global emphasis on energy efficiency, sustainability, and infrastructure development intensifies, the demand for effective pipe insulation solutions is set to rise. Here’s a detailed forecast of what to expect in the pipe insulation market in the coming years.

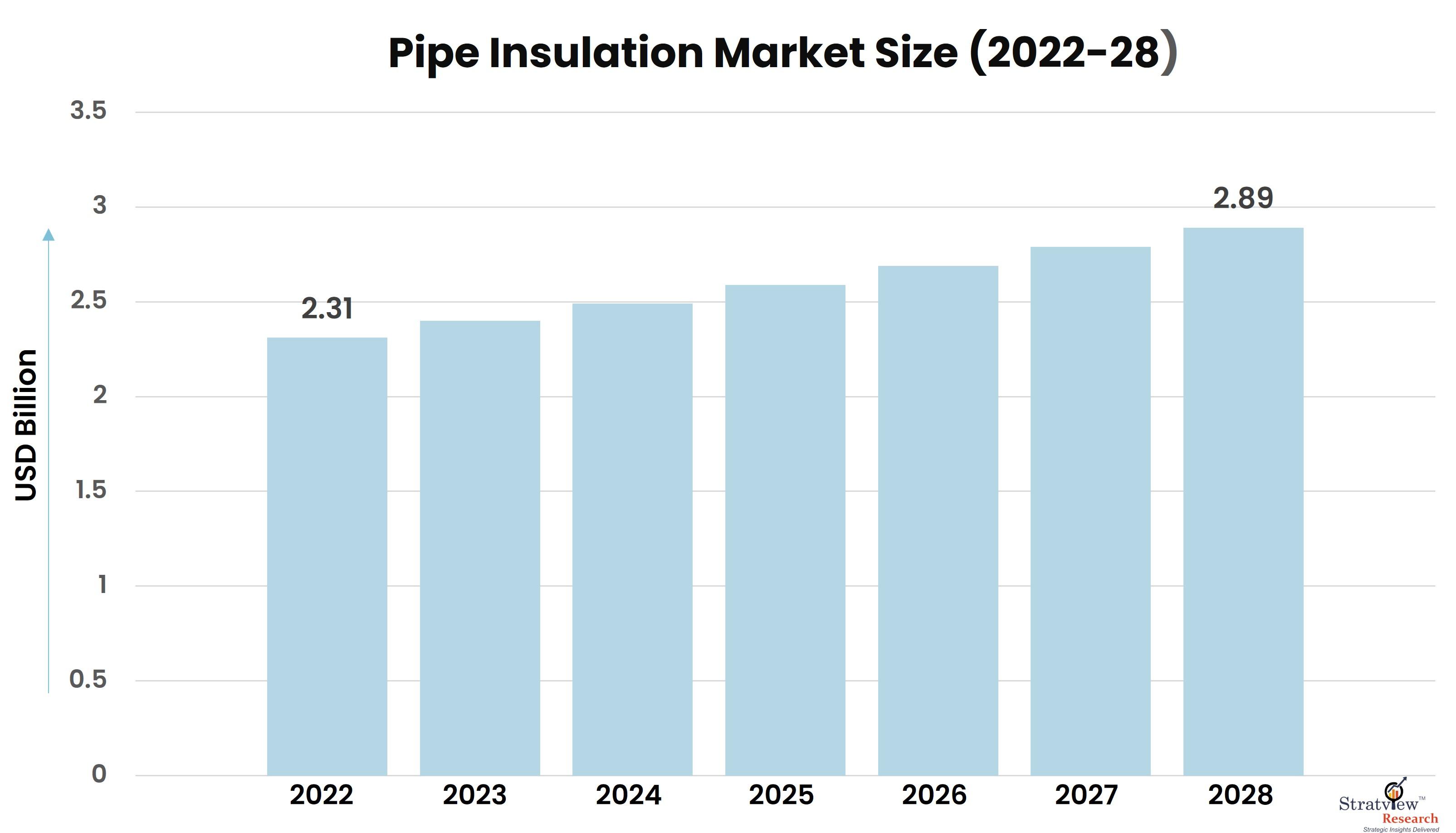

According to Stratview Research, the pipe insulation market was estimated at USD 2.31 billion in 2022 and is likely to grow at a significant CAGR of 3.78% during 2023-2028 to reach USD 2.89 billion in 2028.

1. Steady Growth in Construction and Infrastructure Projects

One of the primary drivers of the pipe insulation market is the ongoing boom in construction and infrastructure projects worldwide. Urbanization and population growth are leading to increased residential, commercial, and industrial construction activities, particularly in emerging economies. This trend is expected to continue, fueling the demand for pipe insulation to ensure energy efficiency and regulatory compliance in new buildings.

2. Enhanced Energy Efficiency Standards

As countries adopt stricter energy efficiency standards and building codes, the pipe insulation market will experience significant growth. Governments and regulatory bodies are increasingly mandating higher insulation standards to reduce energy consumption and greenhouse gas emissions. This regulatory push will drive the adoption of advanced pipe insulation materials in both new construction and retrofitting projects.

3. Technological Advancements in Insulation Materials

The next decade will witness significant advancements in insulation materials and technologies. Innovations such as aerogel insulation, which offers superior thermal performance with minimal thickness, and phase change materials (PCMs) that enhance energy storage capabilities, will gain prominence. These cutting-edge materials will not only improve the efficiency of pipe insulation but also open up new applications across various industries.

4. Growing Emphasis on Sustainability

Sustainability will be a key focus area for the pipe insulation market. As environmental concerns rise, there will be a greater demand for eco-friendly and recyclable insulation materials. Manufacturers will increasingly adopt sustainable practices and develop products with a lower environmental impact. This shift towards greener solutions will appeal to environmentally conscious consumers and businesses, driving market growth.

5. Increased Retrofitting and Renovation Activities

The aging infrastructure in developed regions presents significant opportunities for the pipe insulation market. Retrofitting and renovation projects aimed at improving energy efficiency in existing buildings will be a major growth driver. Upgrading old insulation systems with modern, high-performance materials will be a cost-effective solution for enhancing energy efficiency and reducing operating costs.

6. Expansion of Cold Insulation Applications

The demand for cold insulation, particularly in industries such as food and beverage, pharmaceuticals, and chemicals, will continue to rise. Maintaining low temperatures in processing and storage facilities is crucial for product quality and safety. As these industries expand, the need for reliable and efficient cold insulation solutions will increase, boosting the overall pipe insulation market.

7. Impact of Digitalization and Smart Technologies

The integration of digitalization and smart technologies into insulation systems will revolutionize the market. Smart insulation solutions equipped with sensors and IoT capabilities will enable real-time monitoring and maintenance of insulation performance. This technological leap will enhance operational efficiency, reduce energy consumption, and extend the lifespan of insulation systems.

In conclusion, the pipe insulation market is set for robust growth over the next decade, driven by factors such as increased construction activities, stricter energy efficiency standards, technological advancements, sustainability initiatives, retrofitting projects, and the expansion of cold insulation applications. As these trends continue to evolve, the demand for advanced and efficient pipe insulation solutions will rise, shaping the future of the industry and contributing to a more energy-efficient and sustainable world.