The evaluation of the form and roundness of objects is accomplished through the use of form tracing and roundness testing. Form tracing and roundness testing are two methods that can be used to evaluate the form and roundness of objects. These methods are respectively used to evaluate the sphericity and sphericity of the object. The tracing of forms is one of the options that can be taken advantage of when utilizing these methods.

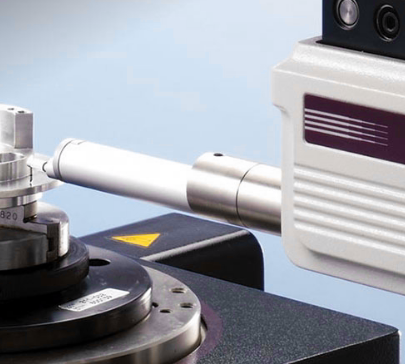

When it comes to determining the form or contour of a surface, a popular type of measuring tool is known as a profilometer, and it is utilized quite frequently. The readings can be interpreted in a variety of ways, and those interpretations can be presented in a variety of formats. As it is moved across the surface, the stylus is able to detect and transmit even the most minute variations in height, and Forming & Roundness Testing Service contours to the surface as it does so. The advantages provided by each of these types are distinct from one another, and the precise nature of those advantages can shift and change depending on the requirements of the application. These various types come with their own individual sets of benefits that are distinct from one another. The information that has been gathered is analyzed so that a calculation can be made to determine the distance from a perfect circle, and any form errors, such as lobing or tapering, can be found so that they can be corrected. If there are any form errors, they can be corrected.

The abbreviation CMM stands for the phrase "coordinate measuring machine," which is what the phrase actually refers to

-

The Coordinate Measuring Machine (CMM) is a multipurpose metrology instrument that can be used for a variety of measurements, such as testing for roundness and tracing the form of an object

-

Its primary function is to measure distances between points on a coordinate system

-

The primary purpose of this tool is to determine the distances that exist between different points on a coordinate system

-

They do this by collecting data points by moving a stylus along the surface of the object as it is being scanned

-

To accomplish this, move the stylus along the surface of the object while doing so

-

CMMs have a high degree of accuracy and are able to measure complex shapes in a manner that is highly repeatable

-

In addition, they are able to measure a wide range of dimensions

-

In addition to this, they have the capability of measuring a wide range of different dimensions

-

Optical profilers offer a number of advantages, including the capacity to measure surfaces despite the degree to which they are rough or smooth, high measurement speeds, and the ability to carry out nondestructive testing

They are particularly useful for things that have surfaces that are sensitive or delicate, as these surfaces tend to be more easily damaged than other surfaces. By measuring parameters such as Ra, which stands for average roughness, Rz, which stands for peak-to-valley height, and Rt, which stands for total roughness, they are able to offer insights into the surface texture of an object. These parameters include peak-to-valley height, average roughness, and total roughness.

What kinds of software do the vast majority of businesses typically employ in order to carry out activities such as form tracing and roundness testing?

Form tracing and testing for roundness are two methods that have a wide variety of applications across a wide variety of commercial markets and industries. Other methods include testing for ellipsis.

The manufacturing process in the aerospace industry places a significant emphasis on both form tracing and roundness testing, which are both very important aspects of the process

-

This is because the aerospace industry is one of the most advanced industries in the world

-

This is due to the fact that testing for roundness and form tracing are both extremely significant components of the process

-

When measurements are taken accurately, it is also possible to manufacture components with improved aerodynamics

-

When measurements are taken accurately, it is possible to manufacture components with improved aerodynamics

-

This is only possible if the measurements themselves are taken accurately

When it comes to the manufacturing of medical devices, precision is of the utmost importance. This is because accuracy not only ensures that the device will function properly, but it also protects the patient from potential harm. The tracing of the component's form and testing the component's roundness are two methods that can be utilized in the process of evaluating components. Another method that can be utilized is the testing of the component's roundness. This system is made up of a variety of components, some of which include prosthetics, surgical needles, implants, and surgical instruments. Components like lenses, mirrors, probes, and calibration standards are put through these tests to ensure that they are of the highest possible quality and level of perfection. These tests are also used to calibrate the standards. These examinations are designed to guarantee that the constituent parts are flawless. If a precision instrument is to function at the highest possible level of accuracy and performance, the form and roundness measurements of the instrument need to be taken with the utmost accuracy. They are helpful for determining the shape and roundness of a variety of components, such as gears, bearings, shafts, molds, and tooling, to name a few of the things on which they can be used.

The shape and roundness of the components can be determined with their assistance. These are the kinds of components that include things like gears, bearings, shafts, and molds, among other things. These measurements are helpful in determining where there are deviations, increasing product quality, optimizing machining processes, lowering wear, and reducing wear overall. They can also be used to reduce wear overall. They are also capable of lowering the overall rate of wear. In addition, these measurements guarantee that electronic devices have an accurate shape. Additionally, the use of these measurements ensures that electronic devices have an accurate shape.

Optics and photonics are two of the fields that require the use of components such as form tracing and roundness testing. These fields also require the use of components like these. Tracing the form of an object and determining whether or not it is round are two activities that are vitally important in the fields of optics and photonics. In order to ensure that the maximum amount of light is transmitted, achieve accurate focusing, and reduce aberrations, it is essential to measure the exact form and roundness of an object. Measuring an object's exact form is also necessary. The reduction of aberrations and the achievement of accurate focusing are two additional objectives of these measurements.