Overview :

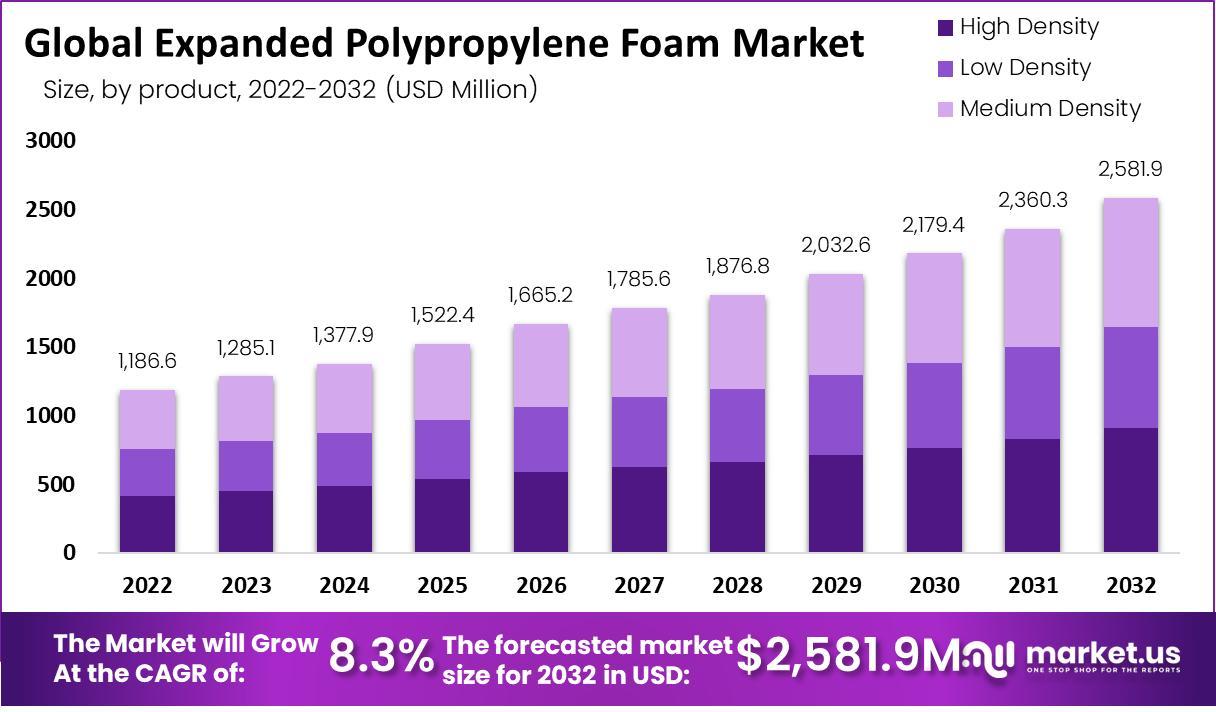

Expanded Polypropylene Foam Market was valued at USD 1,186.6 million and is expected to reach USD 2581.9 million in 2032. This market is estimated to register a CAGR of 8.3% between 2023 and 2032.

Get a Sample Copy with Graphs & List of Figures @ https://market.us/report/expanded-polypropylene-foam-market/request-sample/

Expanded polypropylene (EPP) foam is a versatile material known for its excellent impact resistance and lightweight properties. It is widely used in various industries due to its durability and cushioning ability. In consumer goods, EPP foam provides protection for sensitive electronics like computer equipment and circuit boards, where its shock-absorbing qualities help prevent damage during transport and use. Additionally, EPP foam's insulating properties make it valuable in packaging, building, and construction, where it contributes to energy efficiency and structural integrity.

Looking ahead, the demand for EPP foam is expected to grow, particularly in the toy and sports equipment sectors. As consumers become more health-conscious and seek products that offer better protection and safety, EPP foam's role in these areas is likely to expand. Its use in toys can provide safer play experiences for children, while in sporting goods, it can enhance comfort and injury prevention. This increasing awareness and preference for quality and safety are driving factors that will likely boost the global market for expanded polypropylene foam.

Key Market Segments

Based on Product

-

High Density

-

Low Density

-

Medium Density

Based on Application

-

Bumpers

-

Roof Pillars

-

Seat Bracing

-

Armrests

-

Other Applications

Based on End-User

-

Automotive

-

Packaging

-

Consumer goods

-

Appliances

-

Oil & Gas

-

Other End-Users

By Product Analysis:

The expanded polypropylene (EPP) foam market is segmented into high density, low density, and medium density, with high-density foams leading the market. In 2022, high-density EPP foams commanded over 42.0% of the market share, largely due to their use in automotive safety components and packaging.

By Application Analysis:

In terms of application, bumpers emerged as the leading segment, capturing over 42.0% of the market share in 2022. The increasing need for high-impact-resistant packaging for vehicle components drives this dominance, as EPP foam bumpers provide crucial safety features and impact absorption in automotive interiors and exteriors.

By End-Users Analysis:

The automotive sector is the primary end-user of expanded polypropylene foam, driven by its cost-effectiveness, mechanical strength, and moldability. EPP foam contributes to weight reduction in vehicles, enhancing fuel efficiency by up to 7% and lowering VOC emissions from interior components.

Key Players

-

JSP

-

BASF SE

-

Kaneka Corporation

-

DS Smith

-

Furukawa Electric Co., Ltd.

-

Hanwha Group

-

Sonoco Products

-

Knauf Industries

-

Izoblok

-

Dongshin Industry Incorporated

-

Clark Foam Products Corporation

-

Paracoat Products Ltd.

-

Molan-Pino South Africa

-

Signode Industrial Group LLC

-

Armacel

-

Furukawa Electric Co., Ltd.

-

Other Market Players

Drivers:

The expanding automotive industry is a major driver for the expanded polypropylene (EPP) foam market, as its lightweight and impact-resistant properties are ideal for components like bumpers and panels. Additionally, the growth of e-commerce and the increasing demand for sustainable packaging solutions are boosting the use of EPP foam in the packaging sector.

Restraints:

The high cost and price volatility of polypropylene, a key raw material, can impact profitability and increase finished product costs. EPP foam also faces competition from cheaper alternatives like expanded polystyrene (EPS) and may encounter challenges from emerging materials and technologies.

Opportunities:

There is significant growth potential in the automotive and packaging sectors, with emerging applications in building insulation and cushioning. The development of new uses, such as in toys and sports equipment, and advancements in manufacturing technology could reduce costs and broaden the material’s market reach.

Challenges:

Despite its advantages, EPP foam's market growth may be hampered by the development of new materials that could replace it in certain applications. Limited availability and higher costs associated with its recycling could also affect its overall market adoption and sustainability.