Warehouse Automation Market: Automation for a Smarter Tomorrow

Introduction

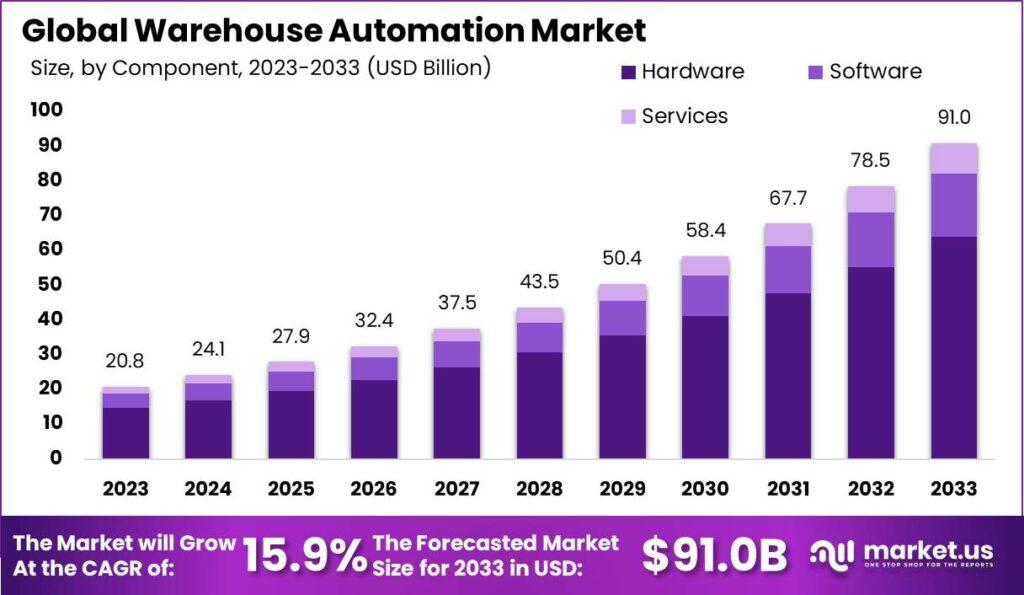

The Global Warehouse Automation Market size is expected to be worth around USD 91.0 Billion by 2033, from USD 20.8 Billion in 2023, growing at a CAGR of 15.9% during the forecast period from 2024 to 2033.

The Warehouse Automation Market is changing how businesses handle their storage and inventory. Companies are looking for faster order fulfillment, driven by the boom in e-commerce and new advances in robotics and AI.

However, there are challenges, such as high upfront costs, difficult integration processes, and resistance from employees worried about job losses. But the benefits are clear: cost savings, better accuracy in inventory management, and the ability to quickly scale operations.

Read More @

https://market.us/report/warehouse-automation-market/

Emerging Trends

AI and Machine Learning: Using AI to predict and optimize warehouse operations.

Collaborative Robots (Cobots): Robots working alongside humans to boost efficiency and safety.

Autonomous Mobile Robots (AMRs): Robots that pick and transport goods within warehouses.

IoT and Smart Warehousing: Connecting devices for real-time data and smarter decisions.

Sustainable Automation: Eco-friendly technologies to reduce environmental impact.

Top Use Cases

Order Picking: Automated systems for selecting and retrieving products.

Inventory Management: Real-time tracking and managing inventory levels.

Sorting and Packing: Automated systems for sorting and packing products for shipping.

Palletizing and Depalletizing: Robots stacking and unstacking pallets.

Transportation: Automated vehicles moving goods around the warehouse.

Major Challenges

High Costs: Big investments needed for automation technologies.

Complex Integration: Difficulty in merging new systems with old processes.

Workforce Resistance: Employees fearing job loss due to automation.

Maintenance and Downtime: Keeping systems running smoothly and handling downtime.

Data Security: Protecting sensitive data from cyber threats.

Market Opportunity

Cost Savings: Automation reduces labor costs and boosts efficiency.

Scalability: Systems can easily scale to meet changing demands.

Accuracy: Improved accuracy in inventory and order management.

Customer Satisfaction: Faster, more reliable order processing.

Innovation: Ongoing tech advancements offer new improvement opportunities.

Conclusion

The Warehouse Automation Market is set for big growth as businesses look to boost efficiency, accuracy, and scalability. Despite some challenges, the advantages and opportunities make warehouse automation a key focus for companies wanting to stay competitive in logistics and supply chain management.

Warehouse Automation Market: Automation for a Smarter Tomorrow

Introduction

The Global Warehouse Automation Market size is expected to be worth around USD 91.0 Billion by 2033, from USD 20.8 Billion in 2023, growing at a CAGR of 15.9% during the forecast period from 2024 to 2033.

The Warehouse Automation Market is changing how businesses handle their storage and inventory. Companies are looking for faster order fulfillment, driven by the boom in e-commerce and new advances in robotics and AI.

However, there are challenges, such as high upfront costs, difficult integration processes, and resistance from employees worried about job losses. But the benefits are clear: cost savings, better accuracy in inventory management, and the ability to quickly scale operations.

Read More @https://market.us/report/warehouse-automation-market/

Emerging Trends

AI and Machine Learning: Using AI to predict and optimize warehouse operations.

Collaborative Robots (Cobots): Robots working alongside humans to boost efficiency and safety.

Autonomous Mobile Robots (AMRs): Robots that pick and transport goods within warehouses.

IoT and Smart Warehousing: Connecting devices for real-time data and smarter decisions.

Sustainable Automation: Eco-friendly technologies to reduce environmental impact.

Top Use Cases

Order Picking: Automated systems for selecting and retrieving products.

Inventory Management: Real-time tracking and managing inventory levels.

Sorting and Packing: Automated systems for sorting and packing products for shipping.

Palletizing and Depalletizing: Robots stacking and unstacking pallets.

Transportation: Automated vehicles moving goods around the warehouse.

Major Challenges

High Costs: Big investments needed for automation technologies.

Complex Integration: Difficulty in merging new systems with old processes.

Workforce Resistance: Employees fearing job loss due to automation.

Maintenance and Downtime: Keeping systems running smoothly and handling downtime.

Data Security: Protecting sensitive data from cyber threats.

Market Opportunity

Cost Savings: Automation reduces labor costs and boosts efficiency.

Scalability: Systems can easily scale to meet changing demands.

Accuracy: Improved accuracy in inventory and order management.

Customer Satisfaction: Faster, more reliable order processing.

Innovation: Ongoing tech advancements offer new improvement opportunities.

Conclusion

The Warehouse Automation Market is set for big growth as businesses look to boost efficiency, accuracy, and scalability. Despite some challenges, the advantages and opportunities make warehouse automation a key focus for companies wanting to stay competitive in logistics and supply chain management.