The printing industry is experiencing a notable shift as the demand for low migration inks continues to rise. These specialized inks, designed to minimize the migration of harmful substances from printed materials into food and pharmaceutical products, are becoming increasingly important due to stringent regulatory requirements and heightened consumer awareness about product safety. This article explores the key drivers behind the growing demand for low migration inks and the trends shaping the market's future.

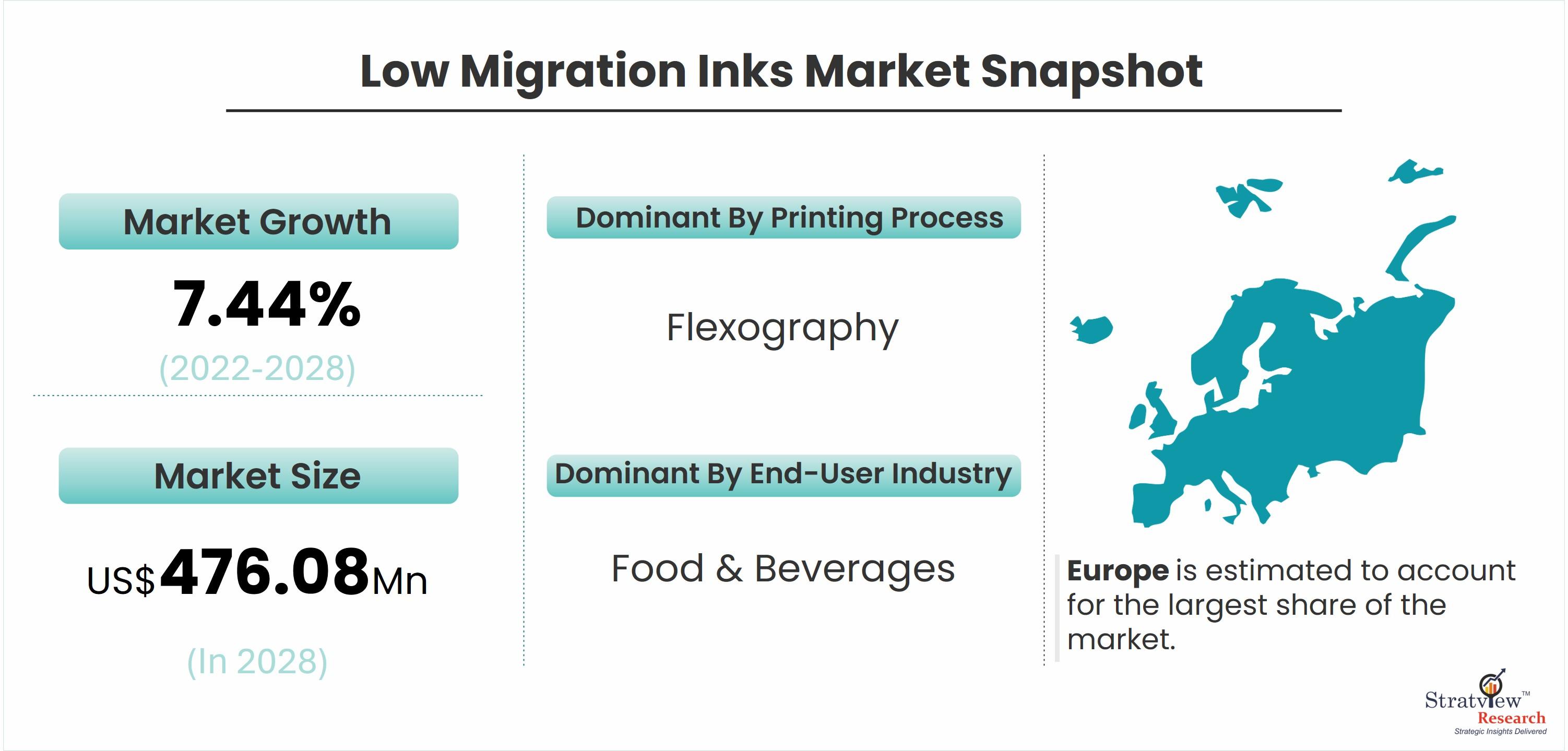

According to Stratview Research, the low migration inks market was estimated at USD 286.44 million in 2021 and is likely to grow at a CAGR of 7.44% during 2022-2028 to reach USD 476.08 million in 2028.

Key Drivers of Demand

1. Stringent Regulatory Requirements One of the primary drivers of the low migration inks market is the implementation of strict regulatory standards aimed at ensuring consumer safety. Regulatory bodies such as the European Food Safety Authority (EFSA) and the U.S. Food and Drug Administration (FDA) have established guidelines to control the migration of potentially harmful chemicals from packaging materials into food and pharmaceuticals. Compliance with these regulations is essential for manufacturers, prompting the adoption of low migration inks to meet safety standards and avoid legal repercussions.

2. Rising Consumer Awareness Consumers are becoming more informed about the potential health risks associated with chemical migration from packaging into products. This increased awareness has led to a demand for safer packaging solutions. Brands are responding by prioritizing the use of low migration inks to ensure their products are safe and free from contaminants. This trend is particularly evident in the food and beverage industry, where packaging safety directly impacts consumer trust and brand reputation.

3. Technological Advancements Advancements in ink formulation technologies are another significant driver of market growth. Innovations in chemistry and manufacturing processes have led to the development of high-performance low migration inks that offer excellent print quality and durability. These technological improvements have expanded the range of applications for low migration inks, making them suitable for a variety of packaging materials, including plastics, paper, and metals.

4. Increasing Demand from the Food and Beverage Industry The food and beverage industry is a major consumer of low migration inks. With the rise of convenience foods and ready-to-eat meals, there is a growing need for packaging that ensures food safety. Low migration inks are ideal for printing on food packaging, as they minimize the risk of chemical contamination and comply with food safety regulations. The trend towards healthier and organic food products further drives the demand for safer packaging solutions.

5. Growth in the Pharmaceutical Sector The pharmaceutical industry is another significant market for low migration inks. The need for secure and safe packaging for medications is paramount, and low migration inks provide the assurance that no harmful substances will migrate into pharmaceutical products. This demand is driven by stringent industry regulations and the necessity to maintain the integrity and efficacy of medications.

Trends Shaping the Future of the Low Migration Inks Market

1. Sustainable and Eco-Friendly Solutions Sustainability is a growing trend in the printing industry, and low migration inks are no exception. Manufacturers are increasingly focusing on developing eco-friendly inks that not only comply with migration standards but also reduce environmental impact. These inks are formulated using renewable resources and minimize the use of hazardous chemicals, aligning with the broader trend towards sustainable packaging solutions.

2. Expansion into Emerging Markets As emerging markets continue to develop economically, the demand for safe and compliant packaging solutions is increasing. Countries in Asia-Pacific, Latin America, and Africa are witnessing a rise in packaged food and pharmaceutical consumption, driving the need for low migration inks. Companies are expanding their presence in these regions to capitalize on the growing market opportunities.

3. Customization and Specialty Applications The trend towards customization and specialty applications is also influencing the low migration inks market. Brands are seeking unique packaging designs to differentiate their products, leading to a demand for inks that can provide vibrant colors and special effects while maintaining low migration properties. This trend is driving innovation in ink formulations to meet specific customer requirements.

4. Collaborative Industry Efforts Collaboration between ink manufacturers, packaging producers, and regulatory bodies is crucial for advancing the low migration inks market. Industry stakeholders are working together to develop standardized testing methods and best practices to ensure product safety. These collaborative efforts are essential for fostering trust and transparency within the industry.

Conclusion

The growing demand for low migration inks is driven by a combination of regulatory requirements, consumer awareness, technological advancements, and increasing demand from key industries such as food and pharmaceuticals. As the market continues to evolve, trends such as sustainability, expansion into emerging markets, customization, and collaborative efforts will shape the future of low migration inks. By staying attuned to these drivers and trends, industry stakeholders can navigate the evolving landscape and capitalize on the opportunities presented by this critical segment of the printing industry.