Aircraft Bolt Market Overview

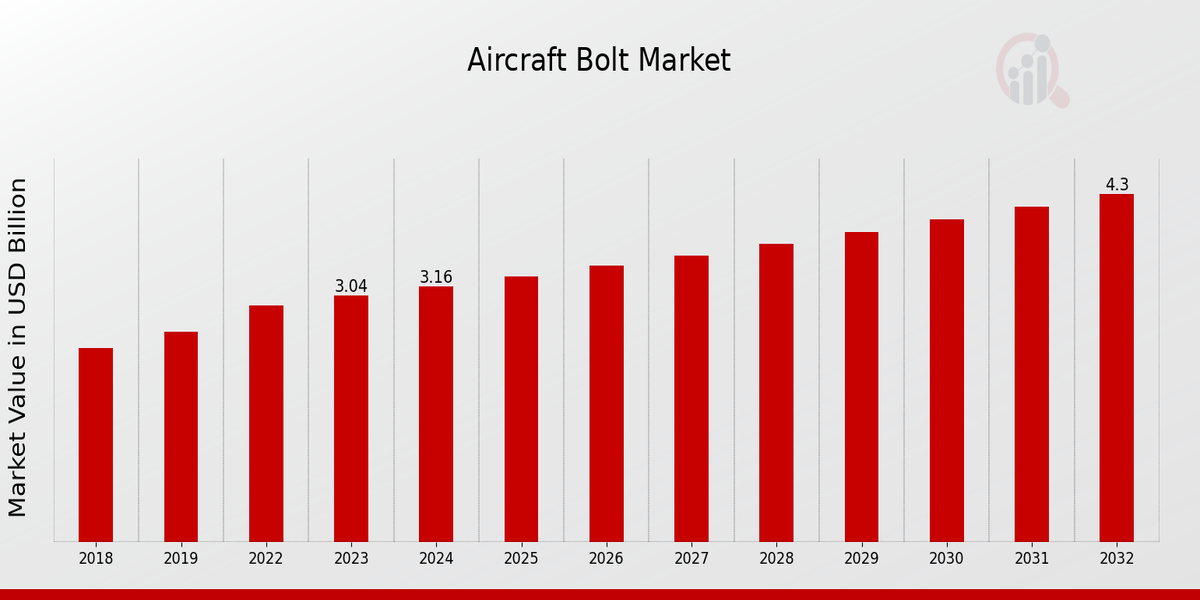

The aircraft bolt market has emerged as a critical component in the aerospace sector, given the rigorous demands placed on modern aircraft for safety, performance, and durability. In 2022, the market size was valued at approximately USD 2.92 billion and is expected to reach USD 3.04 billion by 2023. Projections indicate that the market will continue to expand at a compound annual growth rate (CAGR) of 3.95%, eventually reaching around USD 4.3 billion by 2032. This article delves into the key drivers, challenges, and trends shaping the future of the aircraft bolt market.

Aircraft bolts are critical fasteners used extensively in various structural and non-structural parts of an aircraft. They are essential for maintaining the structural integrity and safety of aircraft. The primary function of these bolts is to join and secure components such as wings, fuselage, engine mounts, and landing gears. Given their crucial role, aircraft bolts are designed to withstand extreme temperatures, pressure variations, and mechanical stress. Their quality and durability directly impact the aircraft's performance and safety.

2. Key Market Drivers

2.1 Increasing Demand for New Aircraft

One of the primary drivers of the aircraft bolt market is the growing demand for new aircraft. The rise in global air travel, driven by increased disposable income and a growing middle class, has led to a surge in orders for both commercial and private aircraft. According to industry reports, major aircraft manufacturers like Boeing and Airbus have reported strong order books, which translate into a higher demand for aircraft bolts and other related components.

2.2 Fleet Modernization Initiatives

Airlines worldwide are focusing on modernizing their fleets to improve fuel efficiency, reduce operational costs, and enhance passenger comfort. This trend is particularly evident in developed markets like North America and Europe, where aging fleets are being replaced with newer, more efficient models. The replacement of older aircraft with modern ones boosts the demand for high-quality, reliable aircraft bolts designed to meet the stringent requirements of new-generation aircraft.

2.3 Stringent Safety and Performance Standards

The aerospace industry is governed by rigorous safety and performance standards set by regulatory bodies such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA). These standards necessitate the use of high-quality materials and components, including aircraft bolts. Manufacturers are increasingly focusing on producing bolts that meet or exceed these regulatory standards, driving innovation and growth in the market.

2.4 Growth in the Defense Sector

The defense sector's demand for aircraft bolts is also on the rise, driven by increasing military budgets and the need for advanced fighter jets, helicopters, and other military aircraft. Governments worldwide are investing heavily in upgrading their military capabilities, leading to a surge in demand for aircraft bolts used in military applications. These bolts are required to withstand extreme conditions, such as high-speed maneuvers and combat situations, further driving the need for specialized, high-strength bolts.

3. Challenges Facing the Aircraft Bolt Market

3.1 Raw Material Price Volatility

The production of aircraft bolts relies heavily on high-quality raw materials, including titanium, aluminum, and specialty alloys. Fluctuations in the prices of these raw materials can impact the cost structure of aircraft bolt manufacturers. Price volatility can arise due to geopolitical tensions, supply chain disruptions, or changes in global demand for metals. Manufacturers must manage these risks effectively to maintain profitability and competitiveness.

3.2 Stringent Regulatory Compliance

While stringent regulations ensure the safety and reliability of aircraft components, they also pose challenges for manufacturers. Compliance with these regulations requires significant investment in research, development, and testing. Manufacturers must navigate complex certification processes to ensure their products meet the required standards, which can increase production costs and time-to-market.

3.3 Supply Chain Disruptions

The global aerospace supply chain is intricate and interdependent. Disruptions in the supply chain, caused by factors such as natural disasters, geopolitical conflicts, or pandemics, can adversely affect the production and delivery of aircraft bolts. The COVID-19 pandemic, for instance, highlighted the vulnerabilities in the aerospace supply chain, leading to delays and increased costs for manufacturers.

4. Emerging Trends in the Aircraft Bolt Market

4.1 Adoption of Advanced Materials

The adoption of advanced materials in aircraft bolt manufacturing is a significant trend. Manufacturers are increasingly using lightweight, high-strength materials such as titanium alloys and composites to enhance the performance of aircraft bolts. These materials offer superior corrosion resistance, high-temperature tolerance, and improved strength-to-weight ratios, making them ideal for modern aircraft applications.

4.2 Digitalization and Automation

The aerospace industry is embracing digitalization and automation to enhance manufacturing efficiency and product quality. Advanced manufacturing technologies, such as additive manufacturing (3D printing), are being used to produce complex aircraft bolts with high precision. Automation and robotics are also being integrated into production processes to improve consistency, reduce human error, and increase production speed.

4.3 Focus on Sustainability

Sustainability is becoming a key focus area for the aerospace industry. Manufacturers are exploring ways to reduce the environmental impact of aircraft bolt production by adopting eco-friendly materials and processes. Initiatives to reduce waste, energy consumption, and emissions are gaining traction, driven by increasing regulatory pressures and consumer demand for sustainable products.

4.4 Increasing Investments in R&D

Research and development (R&D) activities are essential for driving innovation in the aircraft bolt market. Manufacturers are investing in R&D to develop new materials, improve manufacturing processes, and enhance the performance of aircraft bolts. Innovations in bolt design, such as self-locking mechanisms and smart bolts with embedded sensors for real-time monitoring, are being explored to meet the evolving needs of the aerospace industry.

5. Regional Insights

5.1 North America

North America holds a significant share of the aircraft bolt market, driven by the presence of major aircraft manufacturers such as Boeing, Lockheed Martin, and Northrop Grumman. The region's robust defense sector and ongoing fleet modernization initiatives further boost the demand for aircraft bolts. Additionally, the U.S. government's focus on enhancing military capabilities and increasing defense spending supports market growth.

5.2 Europe

Europe is another key market for aircraft bolts, with major players like Airbus, BAE Systems, and Dassault Aviation driving demand. The region's emphasis on sustainability and innovation, coupled with stringent regulatory standards, fuels the demand for high-quality aircraft bolts. The growing focus on electric and hybrid aircraft in Europe is also expected to create new opportunities for aircraft bolt manufacturers.

5.3 Asia-Pacific

The Asia-Pacific region is witnessing rapid growth in the aircraft bolt market, driven by increasing air travel demand, economic development, and expanding defense budgets. Countries such as China, India, and Japan are investing heavily in developing their aerospace capabilities, leading to a surge in demand for aircraft bolts. The region's growing commercial aviation sector and the emergence of low-cost carriers further contribute to market expansion.

5.4 Middle East and Africa

The Middle East and Africa region is experiencing steady growth in the aircraft bolt market, supported by the expansion of the aviation industry and defense sector. Countries like the United Arab Emirates and Saudi Arabia are investing in modernizing their fleets and enhancing their military capabilities, creating opportunities for aircraft bolt manufacturers.

6. Competitive Landscape

The aircraft bolt market is characterized by the presence of several established players and a growing number of new entrants. Key market players are focusing on strategic initiatives such as mergers and acquisitions, partnerships, and collaborations to strengthen their market position. Continuous innovation, product development, and expansion of production capacities are also key strategies adopted by leading companies to maintain their competitive edge.

7. Conclusion

The aircraft bolt market is poised for steady growth, driven by increasing demand for new aircraft, fleet modernization initiatives, and the expansion of the defense sector. While challenges such as raw material price volatility and stringent regulatory compliance exist, the adoption of advanced materials, digitalization, and sustainability initiatives offer promising opportunities for market players. As the aerospace industry continues to evolve, aircraft bolt manufacturers must remain agile and innovative to meet the growing demands and emerging trends in the market.

About US

Market Research Future (MRFR) is a global market research company that takes pride in its services, offering a complete and accurate analysis with regard to diverse markets and consumers worldwide. Market Research Future has the distinguished objective of providing the optimal quality research and granular research to clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help answer your most important questions.

Contact US

Market Research Future (part of Wantstats Research and Media Private Limited),

99 Hudson Street,5Th Floor New York 10013, United States of America

Sales: +1 628 258 0071 (US) +44 2035 002 764 (UK)