Acrylic acid is an organic compound with the chemical formula C3H4O2. It is a colorless, volatile, liquid with a distinctly sharp, unpleasant odor. Chemically, it is the simplest unsaturated carboxylic acid and is formed during the catalytic oxidation of propylene. It has a hydroxyl group (-OH) and a vinyl group (-CH=CH2) which enable it to act as a monomer in many polymerization reactions.

Production

There are two major industrial processes for producing it — the propylene oxidation process and the acetic acid oxidation process. In the propylene oxidation process, a mixture of propylene and oxygen is fed into an oxidation reactor along with a metallic catalyst. The reactor is maintained at high temperatures around 200–350°C and pressures around 2–4 MPa. This causes the propylene molecules to oxidize and form acrylic acid. Some byproducts like acrolein and its esters are also formed and require further separation. The acetic acid oxidation process involves the air oxidation of acetaldehyde over a metallic catalyst at temperatures around 250–400°C to yield acrylic acid and water.

Superabsorbent Polymers

One of the largest applications of it is in the production of superabsorbent polymers (SAPs). SAPs are crosslinked polymers that can absorb and retain large amounts of liquid relative to their own mass. They are produced by reacting it with other comonomers like acrylamide or sodium acrylate. SAPs find extensive use in disposable diapers, adult incontinence products and agricultural/horticultural applications to absorb and retain water for a long time. Around 60–70% of the acrylic acid produced globally is used for manufacturing SAPs.

Adhesives and Sealants

It is commonly polymerized to produce various kinds of adhesives and sealants. Some examples include acrylic adhesives, polyacrylate dispersions and ethylene-acrylic acid copolymers. Acrylic adhesives are known for their high bond strength, resistance to moisture and solvents. They are used to bond a wide variety of substrates like metal, wood, glass and plastics. Polyacrylate dispersions are used as thickening agents and binders in water-based adhesives, paints and coatings. Ethylene-acrylic acid copolymers function as hot melt adhesives and pressure sensitive adhesives due to their ability to transition from a solid to a molten state.

Thickeners and Coatings

Polyacrylic acid and its salts find application as thickening agents, suspending agents and binders in various formulations. Sodium polyacrylate for instance acts as a water retention agent in detergents and is also used as a viscosifier in drilling fluids. Polyacrylic acid often forms the backbone of rheology modifiers which control the flow properties of industrial fluids and consumer products. Its copolymers also serve as binders in water-based paints and coatings, providing properties like durability, gloss and flexibility to the dried film. They are especially used for interior and exterior architectural coatings.

Other Uses

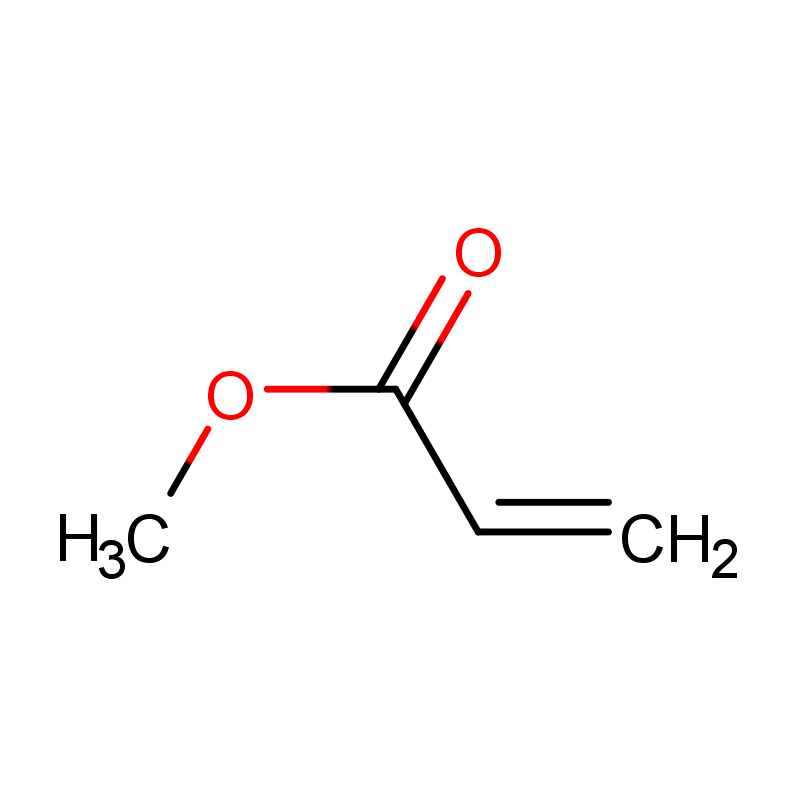

Apart from the major applications above, it has many other smaller scale uses as well. It is polymerized with other comonomers to produce specialty polymers used in products like artificial turfs, baby diapers and feminine hygiene articles. Copolymers of it function as dispersing agents, emulsifiers and surfactants. It is also converted to esters like methyl acrylate which are used in the production of plastics, synthetic rubbers, textiles and surface coatings. Another important derivative is acrylamide which finds application as a flocculating agent in water treatment plants. Overall, the versatile chemistry of acid makes it an indispensable raw material for numerous industrial sectors.

acrylic acid has emerged as one of the most extensively consumed organic compounds globally due to its wide array of applications. Its unique double bond and carboxyl functional group allow it to be easily polymerized or further reacted to synthesize various (co)polymers. Major consuming sectors include disposable hygiene products, adhesives, thickeners/coatings and water treatment. With growing demand from these end use segments, especially in emerging economies, the production and consumption of it is projected to further increase in the future.

French German Italian Russian Japanese Chinese Korean Portuguese

Get More Insights On Acrylic Acid

| https://www.insightprobing.com/blog/acrylic-acid/ |